Lakeview Automotive, Custom Designed and Built Twin Turbo Gen 2 R8 - Calgary AB

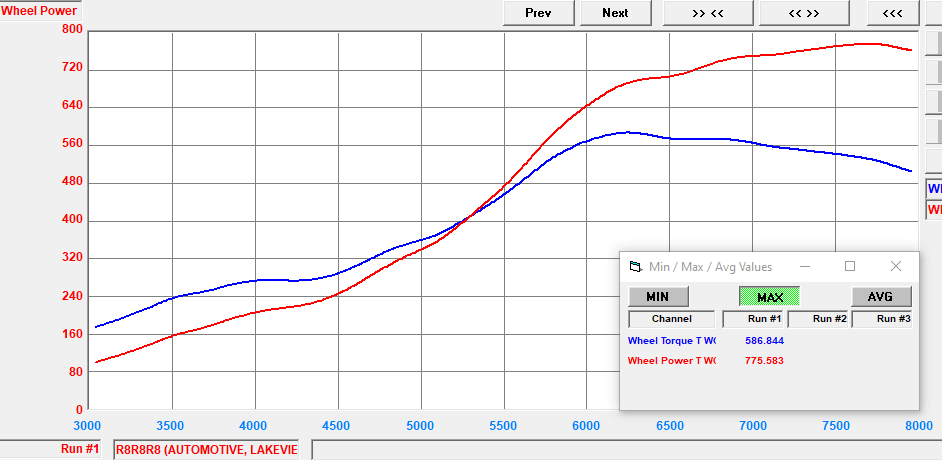

Built. Fabricated. Tuned. Proven — 775 WHP on 93 Octane

(thats around 1000hp at the crank)

Why We Built It?

This 2017 Audi R8 V10 Plus wasn’t built for a client — it was our in-house development car, designed to help us fully understand the Gen 2 R8 / Huracán platform from the inside out. At Lakeview Automotive, we’ve installed several off-the-shelf supercharger and turbo systems, and we continue to support those options proudly. But before taking on customer twin turbo builds for these exotic V10 platforms, we wanted to prove ourselves by engineering and testing our own system — front to back.

By doing it all ourselves — from teardown to fabrication to tuning — we gained a much deeper appreciation for the thermal packaging, electronic integration, and fuelling requirements involved in pushing the Gen 2 R8 to high horsepower reliably.

This wasn’t our first time digging into a V10 either. We previously worked on Dan’s first-gen R8, where we built custom headers and installed a VF Engineering supercharger. That project laid the foundation for our confidence with this more complex Gen 2 platform.

👉

[View Dan’s Gen 1 Supercharged R8 Project]

BUILDER: Sam Gardiner

This Twin-Turbo Audi R8 masterpiece would not have been possible without the exceptional talent and vision of our lead Tech, tuner, machinist, and fabricator, Sam Gardiner. Sam's comprehensive abilities in custom design, CNC machining, and complex fabrication are instrumental in allowing Lakeview Automotive to transform ambitious concepts into reality.

A Break Down Of The Twin Turbo R8 Build

The Turbo System

For this R8 twin turbo build, we selected a pair of VSR Next Gen 67/62 DBB Billet turbochargers — one standard and one reverse rotation — to deliver a perfectly symmetrical layout and ideal performance balance.

These turbos have served us well in past builds. VSR offers exceptional performance for the price, making them a cost-effective choice for in-house development without compromising power or reliability.

What About Other Turbo Options?

While VSR worked perfectly for our R&D build, we have extensive experience with other brands too — and we’re happy to spec any setup to suit the customer’s goals and budget. For client builds, we can use:

- BorgWarner EFR or AirWerks

- Precision Turbo

- Garrett G-Series / GTX Gen II

Or any other brand of your choice

Whether you’re aiming for reliability, ultra-fast spool, or 1,500+ HP capability — we’ll build the turbo system around your needs, not just our preferences.

Core Components:

• VSR Next Gen 67/62 DBB Billet Turbos

One standard rotation and one reverse rotation

1.01 A/R dual V-band housings

Rated to support over 1,100 HP combined

• VSR 44mm Gen 2 Wastegates

Adjustable spring preload

Proven in multiple high-boost applications we've built

• VSR 50mm Blow-Off Valves

Smooth operation under both vacuum and boost

Loud, crisp discharge sound

• V-band Flanges and Clamps

3" and 2.5" stainless steel for both turbine and compressor sides

Ensures leak-free, high-boost sealing

• Turbo Install Hardware Kit

Oil feed and return fittings

Studs, nuts, springs, gaskets, and o-rings

Everything needed to properly secure and route each turbo

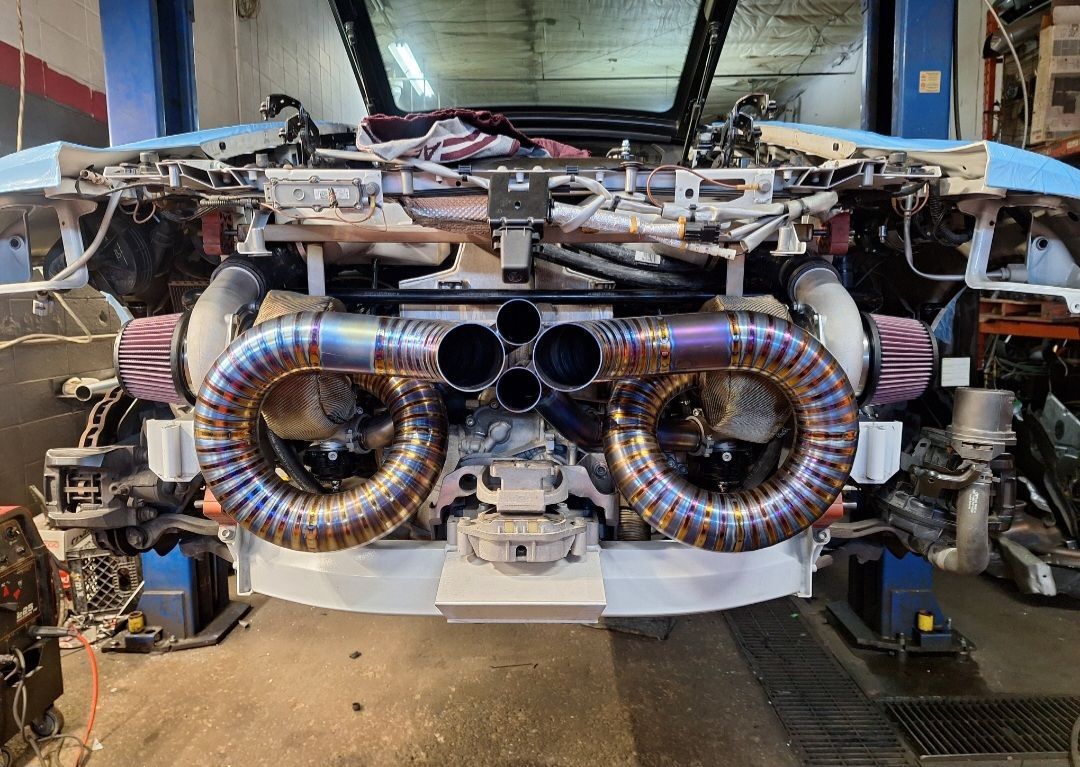

Turbos Mounted In place

🧰 Engineering Symmetry: Turbo Mounting + CNC Bracketry

OEM Mount Points, Mirror Layout, Zero Compromises

To achieve the symmetrical turbo layout you see in the photos above, we had to go beyond just selecting reverse rotation turbos. Sam custom-designed a crossbar mounting system that allows the turbos to hang off the factory exhaust hanger locations — no need for hacking into the chassis or creating janky mounting points.

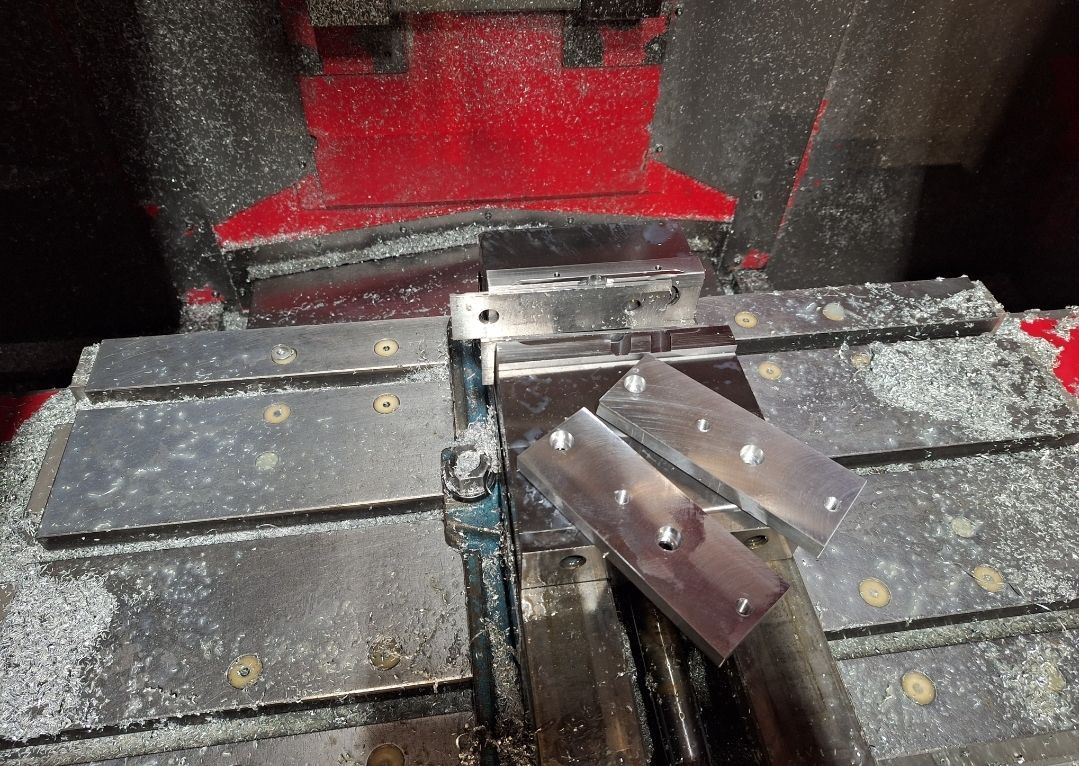

But there was another challenge: clearance for the charge pipes. The factory sway bar positioning interfered with the routing. So, to solve that cleanly, we machined a set of custom CNC sway bar drop brackets, allowing us to lower the sway bar just enough to give proper space for piping without compromising suspension geometry.

What This Gave Us:

🛠 Factory exhaust hanger integration using a custom-fabricated crossbar

🔧 Clean charge pipe routing via CNC sway bar drop brackets

🧲 Mirror-image turbo layout for visual balance

🧵 OEM+ finish with all brackets made in-house

This level of fitment ensures the system can hold up to real-world use, remain serviceable, and maintain the clean aesthetic expected from a platform like the Gen 2 R8.

Cooling & Intake Charge Plumbing

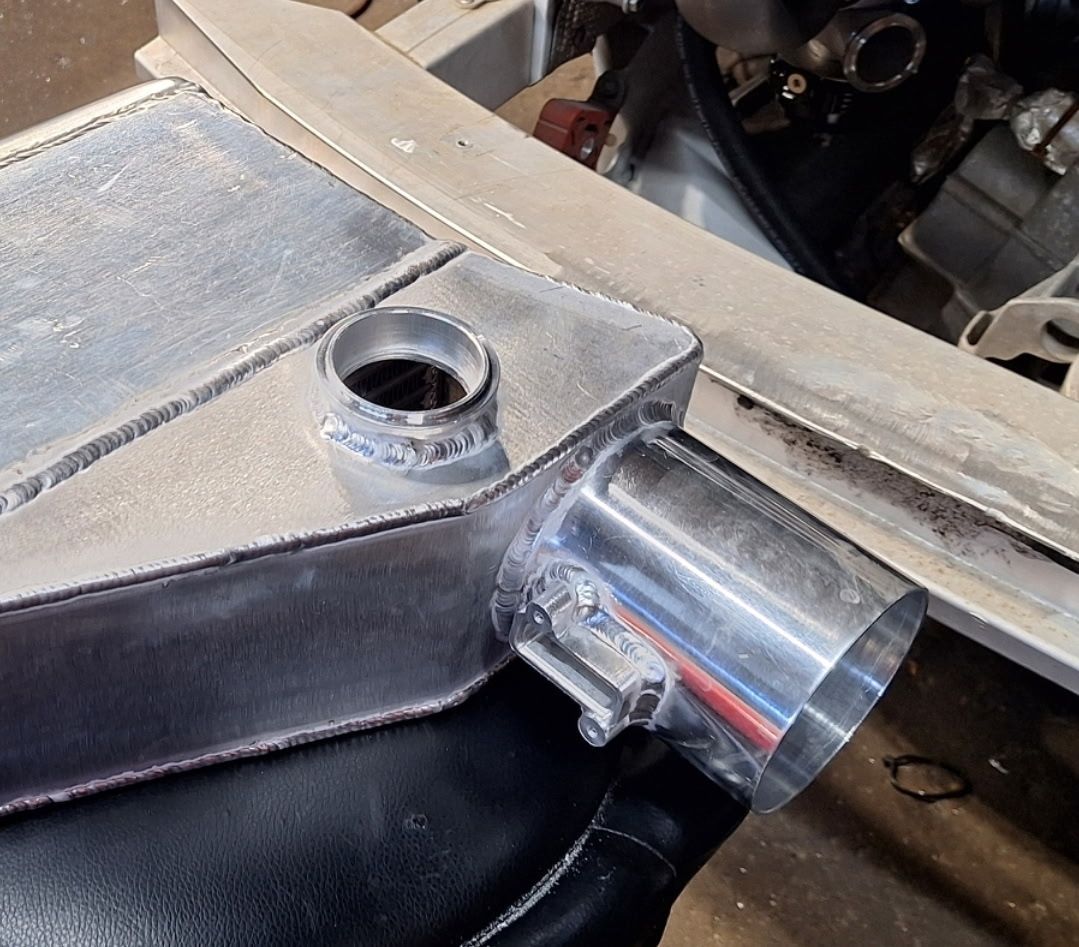

To support the boost from our twin turbo system, we built a fully custom water-to-air intercooler setup specifically tailored to the 2017 R8 chassis.

We started with a pair of oversized water-to-air intercoolers sourced from FrozenBoost, but heavy modifications were required to make them fit and function optimally in the Audi R8’s tight mid-engine bay. The inlet side was converted to a 90-degree welded elbow, while the outlet tanks were fully fabricated to include provisions for dual blow-off valves and OEM-style MAF sensors.

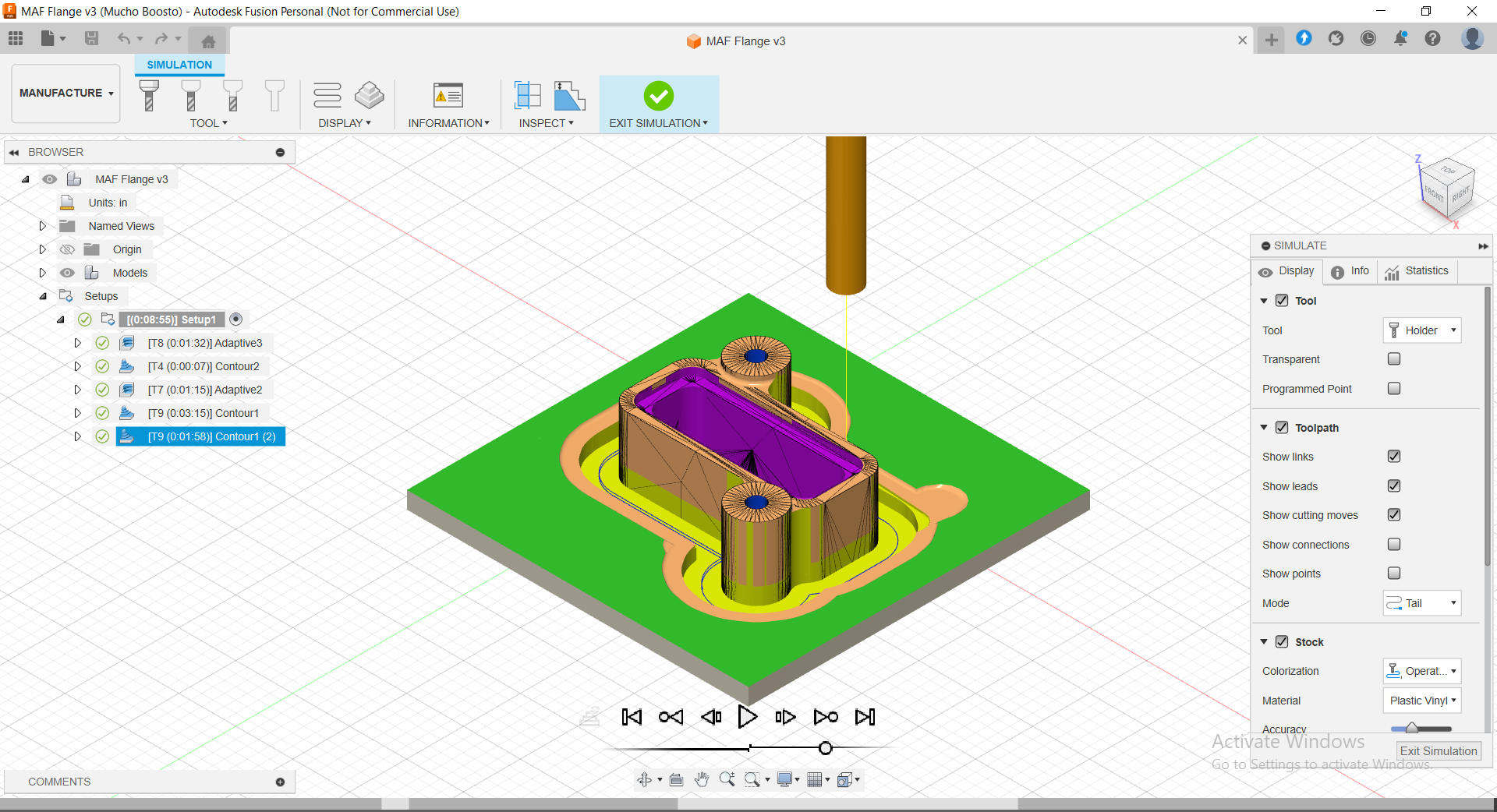

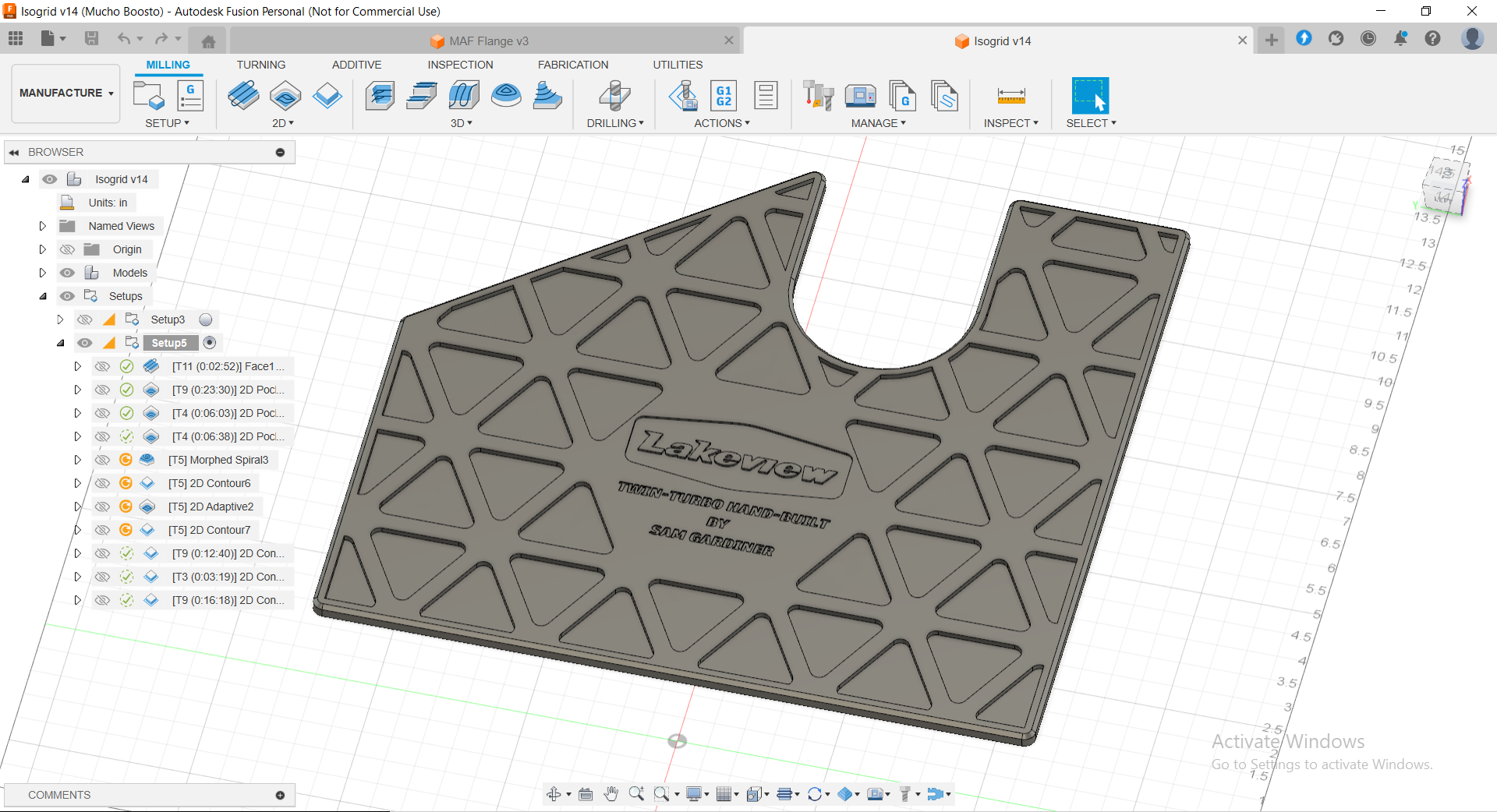

Custom MAF Flanges and CNC Fabrication

Using our in-house CNC mill, we designed and cut custom MAF sensor flanges to retain factory sensor integration — a critical component for clean drivability and accurate air-fuel metering. This allowed us to maintain full ECU functionality without piggyback tricks.

We’ll include photos below of the CAD renderings and live machining of these parts to show the level of detail that went into this build.

Intercooler Radiators and Pump Layout

For cooling, we mounted dual intercooler radiators behind the factory side air intake vents, taking advantage of the R8’s natural airflow path. This keeps intake temps consistent without compromising the clean OEM exterior lines.

We also relocated one of the factory secondary air pumps and reused its space to mount both intercooler pumps securely — a clever bit of packaging that preserved both functionality and serviceability.

Custom Titanium Exhaust Fabrication

Once the turbos were in place and cooling was dialed, we moved on to the exhaust system — and for this build, we didn’t hold back.

We chose to fabricate a full titanium exhaust system for its ultra-lightweight properties, superior heat resistance, and of course, the iconic blue and purple heat coloration that titanium develops when driven hard. This wasn’t just about performance — it was about presence.

Zonda-Inspired Center Exit Design

To highlight the engineering and visual drama of the turbo setup, we cut out the center portion of the rear bumper and created a fully custom center-exit exhaust system. The titanium piping does a tight loop forward before arcing back and exiting out the center, giving it a raw and exposed aesthetic — paired with dual wastegate dumps for maximum visual and auditory impact.

The end result is a wild, motorsport-inspired look that draws clear inspiration from the

Pagani Zonda, reimagined for the Audi R8 chassis. It’s loud. It’s hot. And it’s proudly unapologetic.

Final Thoughts: Lessons from Building Our Own R8 Twin Turbo Kit

This overview is a high-level summary of the design and execution behind our custom twin turbo system for the second-gen Audi R8. Of course, behind the scenes, countless hours were spent routing coolant lines, oil feed and return systems, vacuum references, wiring, and fitting the entire setup in a tight rear-engine bay. But the results speak for themselves.

On just 8 psi of boost, this setup delivered 775 WHP and 586 WTQ on pump gas (93 octane). That’s solid power considering the factory ECU remains untouched and we’re operating well within safe boost limits.

Why We Ran Catalytic Converters — and Why We’d Remove Them

We initially chose to retain the factory catalytic converters for experimental purposes. We understand that in many U.S. states, keeping cats is a legal requirement for compliance. But here in Alberta, we aren’t bound by the same emissions regulations, and this gave us an opportunity to test the limits.

Here’s what we learned:

- The cats do get noticeably hot after repeated pulls — not enough to cause immediate concern, but enough to consider deleting them.

- More importantly, the cats sit directly beneath the water-to-air heat exchangers, essentially acting as a heat source and grille, which raises intake air temps (IATs).

- We planned to develop a thermal barrier/heat shield between the cats and intercoolers, but realistically, removing them altogether is the cleaner solution for high-performance use.

- Just like with any other boosted application, cats do cause a restriction hindering power output.

This heat-related issue isn’t unique to our kit — it’s present on any setup that retains the stock cats.

Power Limits and Future Potential

As most tuners in the boosted R8 and Huracán community know, 8 psi is the reliable ceiling for the factory ECU before a standalone ECU is recommended. Our custom setup uses VSR 67/62 turbos capable of 1,000+ WHP, and the Gen 2 5.2L V10 engine can handle roughly 1,400 HP with the right supporting mods.

With a proper fuel system upgrade and the switch to E85 or race gas, this engine — even in stock form and with this setup— can make 1,000 WHP safely. However, if you plan to run more boost on pump gas, you'd quickly run into detonation risk due to the high factory compression ratio. At that point, a lower-compression engine build becomes necessary, not so much for strength, but for knock resistance under higher cylinder pressures.

Closing Thoughts & Cost Breakdown

At the end of the day, the core function of any twin turbo kit is the same: deliver boost and air to the 5.2L V10 — and most kits on the market, including ours, will do just that from a mechanical standpoint.

The key difference with our system?

It’s not mass-produced. It’s not stamped out of a mold or jig, and theres nothing wrong with that, if we were producing a kit to sell out of our shop we would have it produced on a kit. This is not what we're trying to do, we are building a kit around your vision.

We encourage and love to install kits like Sheepey, VF, AMS, etc., and they’re fantastic. But by going the custom route, you're able to materialize a one-off turbo system that reflects your personal taste — whether that’s function-first, ultra-clean OEM+, or full-blown motorsport-inspired aggression. We’re only limited by imagination and budget.

💰 What Does It Cost to Turbo an R8?

Cost varies depending on:

- Material selection (stainless vs. titanium)

- Turbo choice (VSR vs. Garrett/Precision/etc.)

- Heat exchanger setup

- Exhaust routing (standard exit vs. center exit)

- Fuel system upgrades, ECU strategy, cooling, etc.

But for a cost-effective, stainless-steel setup, using conventional exhaust routing and high-quality components:

✅ Installed and tuned: under $50,000 CAD and up to $75,000 depending on options and complexity.

That puts us in line or slightly under most of the off-the-shelf options, especially when you factor in USD to CAD exchange, shipping, duties, and installation fees.

And unlike other kits — this one is

tailored specifically to you.