Subaru IAG Engines:

A Comprehensive Guide

A Guide to Capabilities, Power Handling, and Recommended Oiling

Quick Links:

IAG Stage 2 TUFF (discontinued)

IAG Stage 4 TUFF (discontinued)

Your Subaru EJ25 STI/WRX has blown up, experienced the infamous “rod knock,” or you’re proactive and want more power out of your Subaru, and want it reliably.

Now, you’re looking into upgraded engine options because, let's face it, the OEM unit is why you’re here anyway. Unless you’re replacing the engine to merely get by and back on the road, putting an upgraded unit such as one of the offerings by IAG Performance is usually the only way to go. However, there are a few options that float out there.

- Buying a used engine.

- An OEM short block.

- Rebuild locally.

- IAG Performance.

Let’s discuss them.

1) Buying a used Subaru engine.

This is a risky option, as 2 out of 5 used EJs we test have bad leak down or compression, or already have rod bearing failure. Nothing is worse than spending time completing the swap — only to find out you have to do it all over again. The 40% chance of that happening is too high for comfort.

Trust us — we've been through this many times over the years of specializing in Subarus. We strictly do not install used Subaru engines here at Lakeview Automotive in Calgary. Even if you buy the engine from a trusted source that will warranty it, they won't pay you back for the time and parts spent swapping if the supplied unit is faulty.

2) OEM short block - and components to make the engines reliable.

This option is okay if you plan to get rid of the car, you're tight on money, or you plan to keep the car at stock power levels. (Or at slightly above power levels — and you promise to take care of it this time. But think about why you are here in the first place).

There are multiple failure points on a Subaru engine you can address to make an OEM short block reliable for years to come at stock power level or slightly above. For starters, address the oiling issues using IAG Performance parts such as the upgraded oil capacity pan and baffles, upgraded IAG oil pickup, and upgrade the PCV system using the IAG air oil separator. And, most importantly, CHANGE YOUR OIL REGULARLY & FREQUENTLY! That takes care of 75% of why the engines blow up in the first place.

The OEM engine can handle around a 20% bump in power, and if you desire more power utilizing mild bolt-ons and tuning, have it tuned professionally on a dyno. We offer pro dyno tuning services here at Lakeview Automotive, using COBB Tuning, or ECUTEK, and our tuners have perfected the Subaru platform. Once the tune is complete, use the same gas you had during the tune, and DO NOT change bolt-ons without getting a re-tune! Tuning, bad gas, and bolt-on swaps without recalibration are the other 25% of why Subarus blow up.

3) Rebuild locally.

Because Subaru engine blocks are split down the middle and held on by bolds, distortion occurs when the heads and other components are bolted together — this makes machining cylinders tricky. Most engine builders are unequipped with that kind of tooling, with some builders electing to machine anyway without the correct tooling. This causes all sorts of issues in terms of engine reliability and longevity.

The second reason you shouldn't: due to high Subaru engine failure rates, companies like IAG Performance have perfected the process of manufacturing “built” Subaru engines. When buying an IAG Performance short block, finished product quality is guaranteed, and when installed through a certified installer like us, it is backed by a 2-year 40k KMS warranty. That's something most engine builders can’t guarantee or offer. Moreover, a local engine rebuild is usually more costly than the OEM or the IAG route.

4) IAG Performance

We became Calgary's IAG Performance dealer because it simply is the best option for all our clients whose Subarus need engines. The Subaru OEM engine is weak, and IAG addresses that by producing engines with stronger pistons, connecting rods, fasteners, close decking of the block surfaces and more precise machining. Their process has been repeated over and over for decades, and with thousands of engines producing immense power worldwide, IAG offers tried and tested consistency.

Each IAG Performance engine starts with a fresh set of case halves (block) with 99.5mm standard bore size. (Higher-level engines are machined to 99.75mm bore size for more controlled piston-to-wall tolerances.) Then each case half is measured carefully, with higher level engines receiving a line honing on the mains and put together utilizing a brand new 2017+ nitride-treated STI crankshaft.

Since the weak point of the OEM Subaru engine is the cast piston, all IAG Performance engines replace the factory connecting rod and piston with a heavier-duty forged counterpart. The Base Stage 2 Block can handle a 40% power increase over stock power, 550BHP, or about 420-450 AWHP on our MD dyno.

Please note that the engines themselves do not produce the jump in power; the supporting mods and tuning does. The engines are rated to withstand higher power outputs.

We will focus on the EJ25 and go through every option IAG Performance offers in that variant. IAG Performance offers EJ20, EJ25 International Hybrid (works with EJ20 heads), and FA-based Subaru engines (direct injected late model WRX, FRS, and BRZ).

IAG 550

Power Level: 550 BHP

This entry-level unit is budget friendly and gets you into the higher power levels reliably. It's entry-level because IAG keeps the bore sizing at 99.5mm. The rotating assembly consists of a 99.5mm JE FSR Forged piston with an asymmetrical skirt design, IAG-Spec H-Beam rods with ARP2000 hardware with ACL or King Race bearings, all bolted to a new Subaru nitride-treated STI crankshaft. Subaru crankshafts are quite strong from factory and won’t need to be upgraded until much higher power levels.

Standard FHI Subaru case bolts are utilized to fasten the case halves together. The compression ratio remains at 8.2:1 on B, W, and V – EJ257 heads. The oil pickup is manufactured using heavy-gauge steel tubing to avoid the cracking failures seen in most OEM oil pickup tubes.

The only downfall with this engine is the probability of piston slap. Piston slap is quite common with forged engines because forged pistons expand and contract with hot/cold cycles more than cast pistons. For that reason, builders give them higher piston-to-wall clearances. Piston slap isn’t necessarily bad; as a side effect of forged pistons, it's simply a noise. Fortunately, it's something the next engine on the list — the IAG stage 2 TUFF — deals with quite nicely.

IAG Stage 2 TUFF - Discontinued

Power Level: 600 BHP

The IAG stage 2 TUFF is our go-to choice of Subaru engines. We stock these on our shelf here at Lakeview Automotive. The IAG Performance Stage 2 TUFF adds on to the Stage 2 2.5L Subaru Short Block with heavier-duty internals. The changes include heavier-duty IAG-spec H-Beam forged rods and heavier-duty and boxed style 99.75mm pistons. The cylinder is bored and honed to accommodate 99.75mm pistons, allowing better control over piston-to-wall clearances. In turn, this results in a quieter running engine, with minimal forged piston slap.

Standard case bolts and standard-sized 11mm ARP head studs are still used in this application. As well, the compression ratio remains at 8.2:1 on B, W, and V – EJ257 heads. The Stage 2 Tuff is good for higher power outputs and the occasional track day duty. Need more convincing? It's what we install on 90% of our builds.

IAG 750

Power Level: 750 BHP

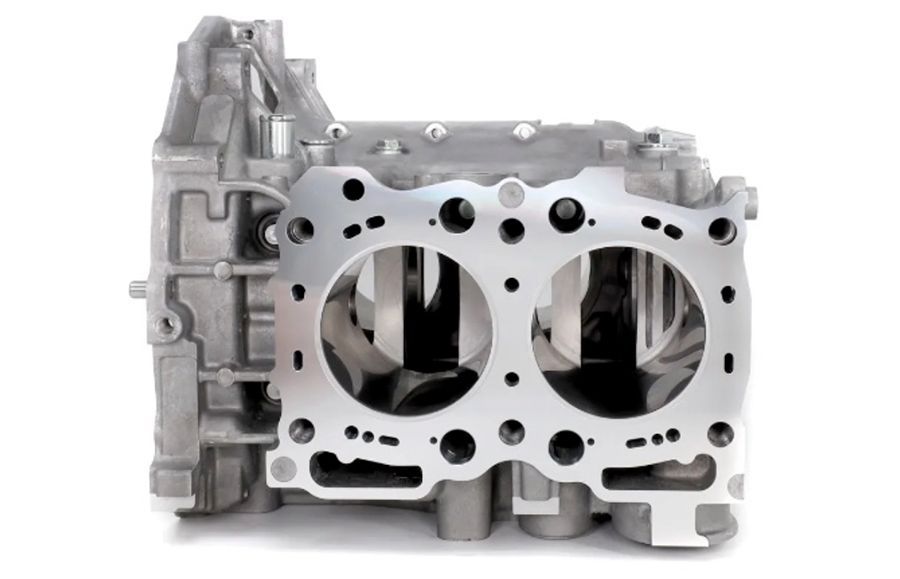

700 BHP is serious power on a Subaru — after all, it's only a 2.5L. IAG achieves this power output rating by close decking the block surface (pictured above). At anything above 600 BHP, boost and cylinder pressures are relatively high; with the OEM deck design being mostly open, the cylinders lack the support needed at such pressures. The lack of support and high pressures cause cylinder distortion that can cause cracking in the cylinder walls — not good.

Close decking is a process where an insert is machined to fit perfectly around the open areas of the deck surface. This insert supports the top of the cylinders, holding them in place under high pressures. Other than that, the Stage 2.5 uses the same piston as the Stage 2 TUFF, only with a thicker rod and wrist pin.

Standard case bolts and standard-sized 11mm ARP head studs are still used on this application. Also, the compression ratio remains at 8.2:1 on B, W, and V – EJ257 heads.

IAG 950

Power Level: 950 BHP

At this power level, three things get addressed and built upon the Stage 2.5.

- The introduction of the Fire-Lock head gasket system.

- The machining of the block to accept 14mm head studs.

- The IAG H Beam-Rods are lengthened by 2mm.

The Fire-Lock head gasket system is loosely derived from the diesel world. At such high power levels and combustion pressures, the seal between the head and the block becomes a weak point. The head gasket and the clamping force of the head studs achieve the seal. To strengthen the head gasket seal, IAG machines a counterbore in the block designed to fit specially-made stainless-steel rings that carry the heavy load of sealing the combustion chamber, aiding the head gasket.

The block is then machined to accept 14mm head studs to allow for higher clamping force. Again, at such high combustion pressures, the heads want to lift off the block. At this point, the factory sized 11mm head studs will fail, causing the head to lift and break the seal. ARP 14mm head studs are utilized to alleviate this issue.

The Rods are lengthened by 2mm to help decrease piston speeds, help with rod angle, and increase dwell time at top dead center and bottom dead center. Decreased rod angle helps with lowering piston side load while decreased piston speed helps at high RPM by increasing TDC dwell time. (This prolongs the compression event). IAG also redesigns the piston to accommodate for the extra 2mm of rod by raising the wrist pin up the piston.

Standard case bolts, and standard-sized 11mm ARP head studs are still used on this application. Once again, compression ratio remains at 8.2:1 on B, W, and V – EJ257 heads.

IAG Stage 4 TUFF - Discontinued

Power Level: 1000 BHP

Out of the box 1000 BHP capable! The Stage 4 Tuff carries over from the Magnum in terms of the Fire-lock sealing system and close decking. However, the rods are now a heavier-duty I-beam design, and the piston and wrist pin have been beefed up to accommodate higher output levels. Moreover, the closed deck is further reinforced by plug inserts, where a vulnerable case bolt access would be.

Std. 11mm ARP head studs are still used on this application. Also, the compression ratio remains at 8.2:1 on B, W, and V – EJ257 heads

IAG 1150

Power Level: 1150 BHP

This is some serious drag racing power. Everything is carried over from the Stage 4 Tuff at this level — plus a wristpin, crank, and case half hardware upgrade.

The Subaru engine (by design) has one major flaw. It is split in half because of its nature as a boxer engine. The case halves are fastened together around the crankshaft with case bolts, meaning the halves are not pinned together from factory. At a power output rating of 1100 BHP, this becomes a problem — the case halves start moving on each other and try to split apart.

As a solution, IAG machines the case halves to take dowels and upgrades the case bolts to ARP counterparts that can be torqued to a higher spec, increasing clamping power. This solution also requires the case halves to be line honed together for precise fitment of the main bearings.

While the 2017+ nitride STI crankshaft is incredibly strong for an OEM unit, at 1100 BHP, it’s time for an upgrade. IAG uses an upgraded billet crank with upgraded oiling passages.

IAG Stage X

Power Level: 1100 BHP+

This is it. This is the biggest, baddest, wildest Subaru block you can get. It’s a full billet block, made from scratch — this enabled IAG / Crest CNC to make a Subaru block from a clean slate, addressing all the weak points of the OEM block.

Each block is machined from 6061 Aerospace Aluminum, utilizing Darton Ductile iron sleeves, and strengthened everywhere the OEM block could have used some help. It also features additional bolts around the case halves to increase clamping force. The Stage X uses the same rotating assembly from the Stage 4 Extreme and keeps the factory compression ratios.

By now, you may ask — why do we keep upgrading pistons and rods and not start off with the strongest set?

The answer is weight. Heavier-duty pistons, wrist pins, and rods are heavier than their lighter-duty counterparts. So if you’re not chasing that kind of power it's better to keep the rotating mass in the engine as low as possible. With IAG blocks, it's always good to match your power goals with what block you choose.

Along with any Subaru engine build, we always recommend the following parts from IAG Performance to further enhance reliability, longevity, and performance over the OEM oil pan, OEM oil pickups, etc.:

- Upgraded oil pump (IAG Stage 2 CNC oil pump).

- Upgraded oil pan, IAG oil control baffle, and pick up (requires the IAG oil pickup spacer when used with Killer B Oil Pan).

- IAG Performance AOS (street or competition).

With IAG Performance being so dedicated to the Subaru community, and with its solid track record of producing the best Subaru engines in the world, we look no further for our choice of engine builder. With the vast array of options to fit any power goal, and best of all, warranty, why would you look any further?

Contact Us for quotes or if you have any questions!